- Company

- Products

- Antistatic Masterbatch

- Conductive Masterbatch /Plastic Composite Masterbatches (MOS2 / PTFE) (Antibacterial Masterbatch) (CFRTP/103~104) Ω,cm

- PA6.PA66 Plastic Composite Masterbatches (Non-halogen / Flame Retardant)

- PA6-Repro Pellet / PA6-Virgin Pellet

- PA66-Repro Pellet / PA66-Virgin Pellet

- PA6/PA66 Plastic Composite Masterbatches (Glass Fiber / GFRTP)

- PBT Engineering Plastics

- Plastic Composite Masterbatches (Super Tough)

- Q.C Lav

- E-catalog

- Contact Us

PRODUCTS

Engineering plastic grade nylon pellets

- Engineering plastic grade low viscosity nylon

- Engineering plastic grade medium viscosity nylon

- Engineering plastic grade high viscosity nylon

-

USE:

Injection Grade, Electrical Parts, Infromation Equipment Parts, Tool Housing, Injection and Extrusion, Mixing, Cut Cotton, Sports Equipment, Gear, Car Parts, Carpet, Extrusion, Fishing Net, Monofilament, Seat Belt, Packaging Film

Nylon composite material

The main products and features

- Injection grade, glass fiber reinforced grade, special reinforced grade/li>

- Toughening grade, glass fiber toughening grade

- Flame retardant grade, glass fiber flame retardant grade, weatherproof grade

- Antibacterial products

- High viscosity in nylon 6

- The main supply of tool casings, sports equipment, electrical parts, steam locomotive components, consumer products and other purposes.

- With light weight, high strength, convenient processing and molding, excellent elasticity, chemical resistance, and good weather resistance, it gradually replaces wood and metal alloys and becomes the main source of new materials.

Antistatic Masterbatch

- These masterbatches are based on fatty acid ester type of anti-static agents to neutralize the charges on the surface of the polymer. By using anti-static additives, problems caused by static electricity charge will be reduced or eliminated. These problems are:

- Dust pick up which can ruin clarity and surface finish. Handling problem- e.g.,Mutual repulsion of bodies of the same charge in polymer based packing. Electronic static discharge damaging electronic equipment.

- AddKan Antistatic Masterbatches works by migrating to the surface of the polymer. It functions usually in a molecular or multi-molecular layer and attracts water molecules from the atmosphere. The water lowers the surface resistivity from the approximate value of 1014 – 1015 ohm for most polymers (including styrenics and polyolefinics) to 1011- 108 ohm . Normal addition levels of the 10% active content masterbatch is 3%.

-

Antistatic Masterbatches for appliance parts :

These components are used in manufacturing of appliances parts which are used in washing machines, refrigerators etc. Precautions should be maintained to keep these parts dust free owing to accumulation of static charges. These Masterbatches are developed using carefully selected anti-static agents that induce the conductivity to the components, eliminating static charges without affecting aesthetics of the components including clarity, etc. - Antistatic Masterbatches for electronic applications :

The use of anti-static agents in polymer components of electronic applications plays a pivotal role, as static charges can result in electronic discharge e.g. when films come in contact with sensitive electronic equipment during packing or when electronic components stored in plastic bin for longer period can damage the components. We offer anti-static masterbatches based on amine derivative agents for the above application even under low relative humidity condition.

- ABS (Surface Resistivity / Co-Extruded or Laminated with Regular ABS)

- PS (Surface Resistivity / Co-Extruded or Laminated with Regular HIPS)

- Nylon (Surface Resistivity / Wear Resistance / Low Temperature Impact Resistance)

- PP (Surface Resistivity / Acid, Alkali or Chemical Resistance)

Conductive Masterbatch/Plastic Composite Masterbatches (MOS2 / PTFE) (Antibacterial Materials)

(CFRTP/103~104) Ω,cm

PA6.PA66 Plastic Composite Masterbatches (Non-halogen / Flame Retardant)

PA6-Repro Pellet / PA6-Virgin Pellet

PA66-Repro Pellet / PA66-Virgin Pellet

PA6/PA66 Plastic Composite Masterbatches (Glass Fiber / GFRTP)

- PA6-G3051SD/30%GF-Semi dull(Virgin) Masterbatch

- PA6-G3052SD/30%GF-Semi dull Masterbatch

- PA6-G4351SD/40%GF-Semi dull(Virgin) Masterbatch

- PA6-GM9040NC/50%GM-Natural(Virgin) Masterbatch

- PA6-G3012/30%GF-Black Masterbatch

- PA6-G3014A/30%GF-Black(Rohs) Masterbatch

- PA6-G4014A/40%GF-Black(Rohs) Masterbatch

- PA6-G3063NC/30%GF-Natural(Virgin) Masterbatch

- PA6-G4064NC/40%GF-Natural(Virgin) Masterbatch

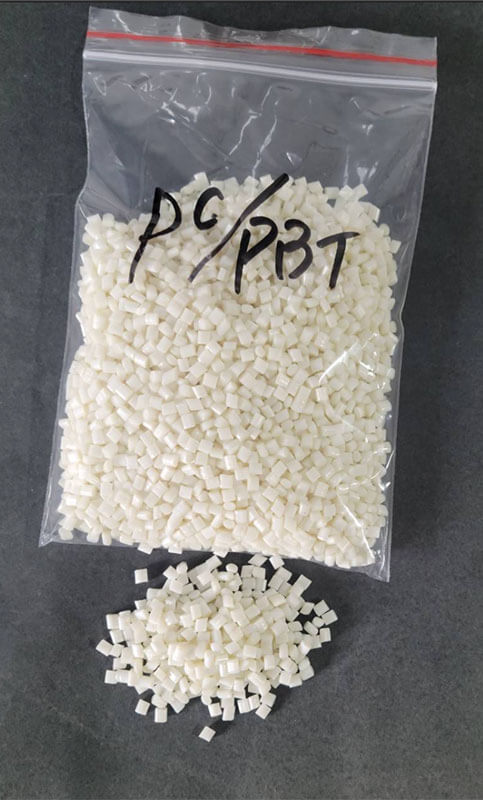

PBT Engineering Plastics

Plastic Composite Masterbatches (Super Tough)

- PA/PP-810(Virgin)-Semi dull (-20°C Izod impact=50kg.cm/cm) Masterbatch

- PA/ABS-809(Virgin)-Semi dull (-20°C Izod impact=35kg.cm/cm) Masterbatch

- PA6/ST900/Black(Super tough) (-40°C Izod impact=30kg.cm/cm) Masterbatch

- PA66/ST806/Black(Super tough)Super tough (-40°C Izod impact=35kg.cm/cm) Masterbatch

- PA6/ST915/Natural (Virgin)/Super tough (-40°C Izod impact=35kg.cm/cm) Masterbatch

- PA66/ST805/Natural (Virgin)/Super tough (-40°C Izod impact=40kg.cm/cm) Masterbatch

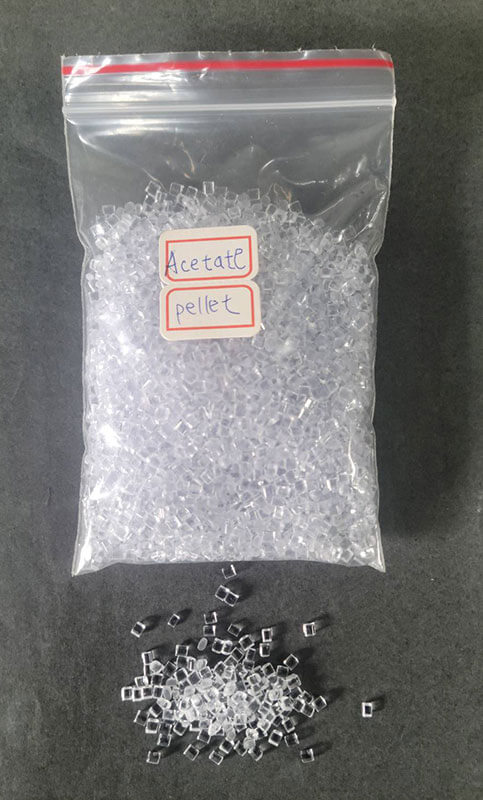

Acteate Pellet

PC/PBT

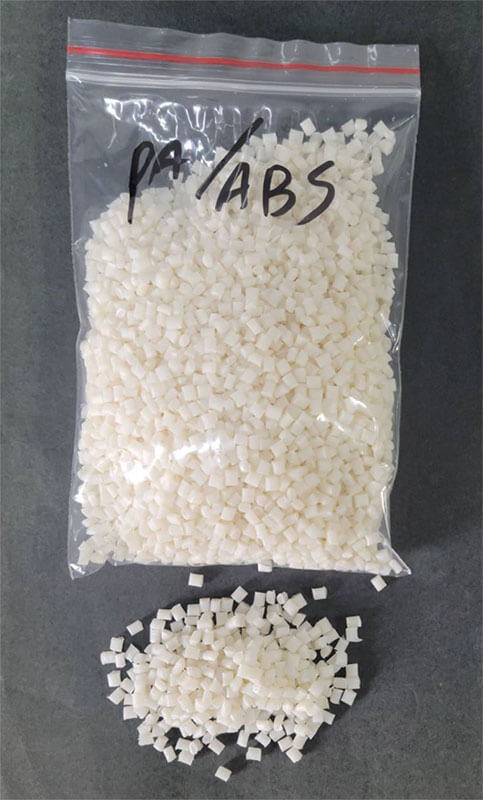

PA/ABS